Reduce operating expenses with our H2 regeneration system upgrade for bright annealing lines

Request a free of charge, non-binding quote today!

If your bright annealing line has been hit hard by the high price of hydrogen, we have the solution for you:

a fully integrated EBNER H2 regeneration system!

Bright annealing lines for stainless steels and copper alloys typically use process atmospheres with high hydrogen contents (up to 100 % H2). This inhibits oxidation of the strip surface during the heat treatment process.

However, the consumption of hydrogen atmosphere represents a significant cost factor during operation of such facilities (OPEX). When combined with the constantly increasing price of utilities, it is obvious that is crucial for companies to optimize operating costs – and a system that recycles hydrogen atmosphere is an excellent way to do so.

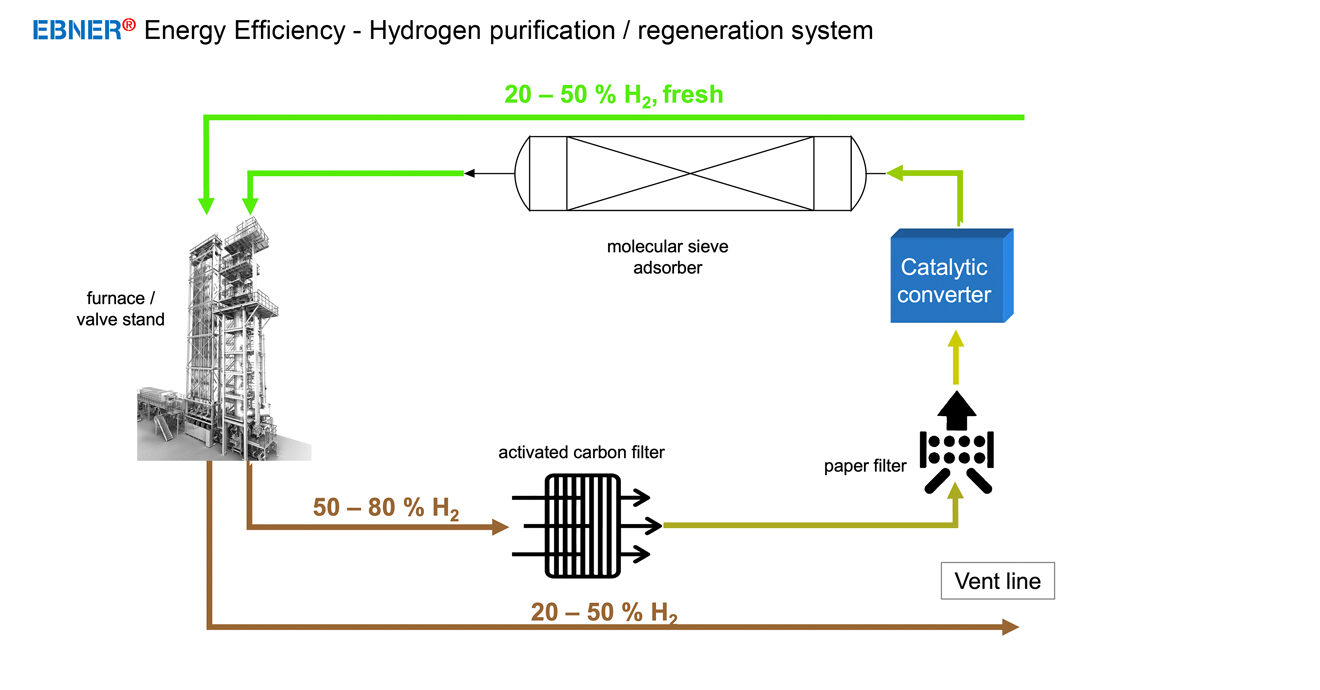

An EBNER hydrogen regeneration system can significantly reduce hydrogen consumption during processing. It does so by drawing off hydrogen atmosphere, which has been contaminated with moisture, evaporated drawing compound and other impurities, through ducting installed at the inlet lock of the furnace and forcing it through a multi-stage purification unit. This unit incorporates an activated carbon filter, an auxiliary filter, a catalytic converter and a molecular sieve adsorber, which prepare the atmosphere for re-use. Once purified, the clean gas is returned to the heat treatment facility.

Fully integrated EBNER H2 regeneration systems are now achieving recycling rates of up to 80 %, without affecting the surface finish of the heat treated strip or the reliability of the facility.

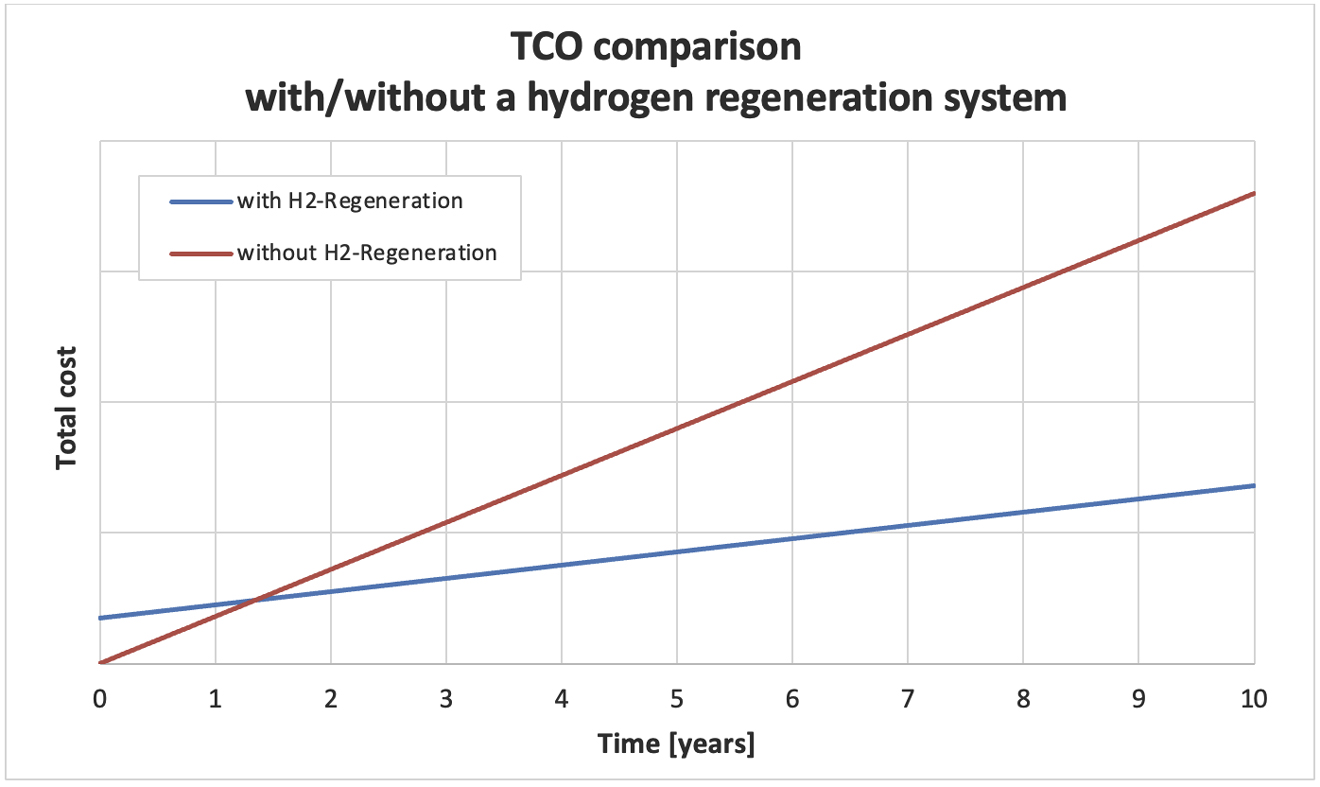

Depending on facility throughput and current utility prices, an amortization period of only 1 – 3 years can be expected. For example, given a facility with an annual throughput of 40,000 metric tons and a hydrogen price of € 0.90/m³, the Total Cost of Ownership (TCO) can be depicted as follows: